关于multiphaseEulerFoam中固相摩擦黏度的计算问题

-

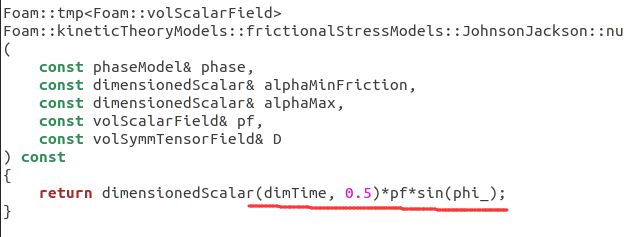

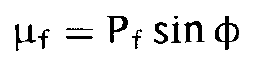

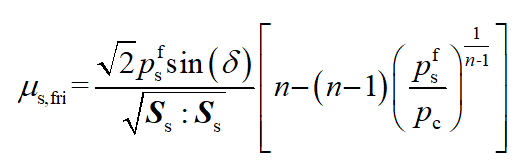

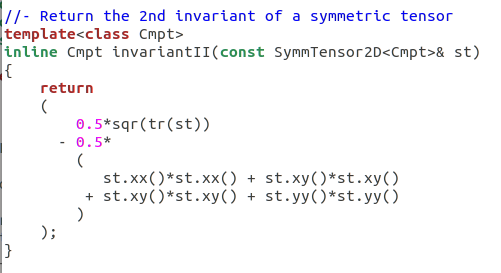

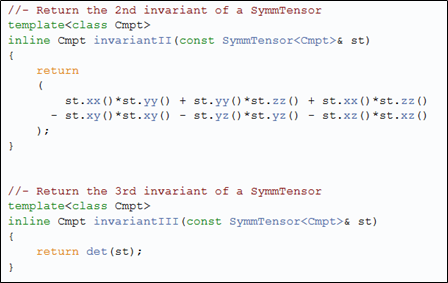

@李东岳 东岳老师,从下面几个式子看,固相黏度应该都是半经验表达式,所以0.5可能是个实验获得的参数:

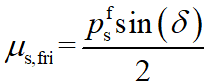

(JJ)

(JJ)

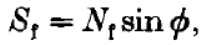

(Schaeffer)

(Schaeffer)

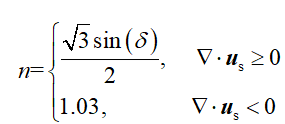

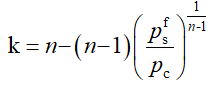

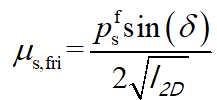

(Princeton)

(Princeton)此外,princeton中摩擦应力计算如下:

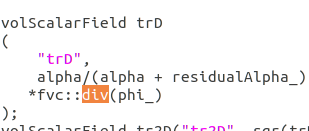

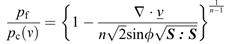

对通量的处理:

const volVectorField& U = phase.U(); surfaceScalarField phiU = fvc::interpolate(U) & U.mesh().Sf(); volScalarField Ud = fvc::div(phiU);对压力计算:

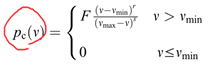

const volScalarField pc = Fr_*pow(max(alpha - alphaMinFriction, scalar(0)), eta_) /pow(max(alphaMax - alpha, alphaDeltaMin_), p_); ...... //对体 forAll(n,celli) { if (Ud[celli] < 0.0) { n[celli] = 1.03; } else { n[celli] = 0.5*sqrt(3.0)*sin(phi_.value()); } m[celli] = n[celli]-1; //..No negative base. 对不对? pt[celli] = 1.0-Ud[celli]/( n[celli]*sqrt(2.0)*sin(phi_.value())* (sqrt(Us[celli]) + small) ); if (!(pt[celli] > 0.0)) { pt[celli] = small; } //..No negative exponent. if (m[celli] > 0) { //n-1 power pt[celli] = pc[celli]*pow(pt[celli], m[celli]); } else { pt[celli] = pc[celli]*pow(1/pt[celli], mag(m[celli])); } } ...... //对面 forAll(currPatch,facei) { if(UdBf[patchi][facei] < 0.0) { nBf[patchi][facei] = 1.03; } else { nBf[patchi][facei] = 0.5*sqrt(3.0)*sin(phi_.value()); } mBf[patchi][facei] = nBf[patchi][facei]-1; ptBf[patchi][facei] = 1.0-UdBf[patchi][facei]/( nBf[patchi][facei]*sqrt(2.0)*sin(phi_.value())* (sqrt(UsBf[patchi][facei]) + small) ); if (!(ptBf[patchi][facei] > 0.0)) { ptBf[patchi][facei] = small; } //..No negative exponent. if (mBf[patchi][facei] > 0) { ptBf[patchi][facei] = pcBf[patchi][facei]*pow(ptBf[patchi][facei], mBf[patchi][facei]); } else { ptBf[patchi][facei] = pcBf[patchi][facei]*pow(1/ptBf[patchi][facei], mag(mBf[patchi][facei])); } } } // Correct BCs pt.correctBoundaryConditions(); Us.correctBoundaryConditions(); Ud.correctBoundaryConditions();黏度计算:

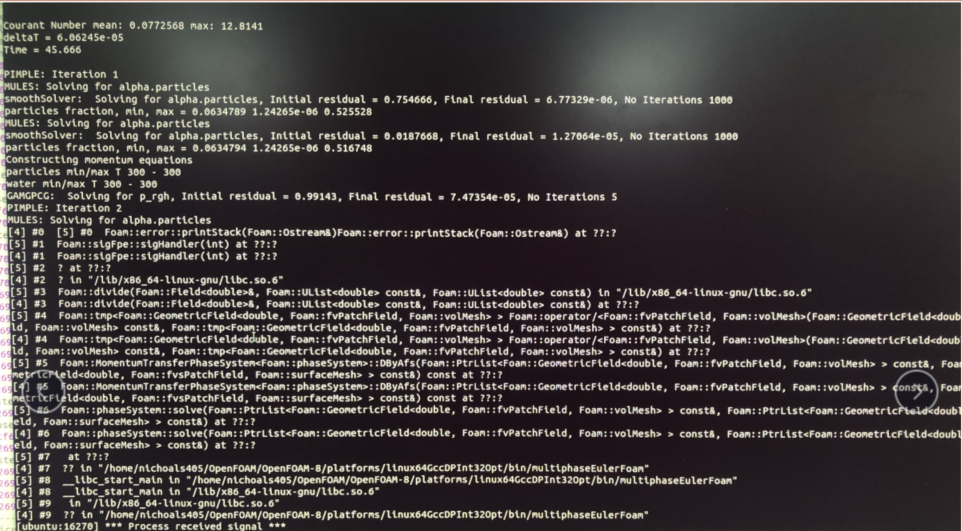

//对体 forAll(Ud,celli) { if (Ud[celli] < 0) { n[celli] = 1.03; } else { n[celli] = 0.5*sqrt(3.0)*sin(phi_.value()); } m[celli] = n[celli]-1; if (!(pc[celli] > 0)) { pc[celli] = small; } //..pf is a const. //calculation of nu if (m[celli] > 0) { nu[celli] = sqrt(2.0)*pf[celli]*sin(phi_.value())* ( n[celli]-(n[celli]-1.0)*pow(pf[celli]/(pc[celli]), 1/m[celli]) ) /(sqrt(Us[celli]) + small); } else { nu[celli] = sqrt(2.0)*pf[celli]*sin(phi_.value())* ( n[celli]-(n[celli]-1.0)*pow(pc[celli]/(pf[celli]+small), mag(1/m[celli])) ) /(sqrt(Us[celli]) + small); } } ...... //对面 forAll(patches, patchi) { if (!patches[patchi].coupled()) { const fvPatch& currPatch = patches[patchi]; forAll(currPatch,facei) { if(UdBf[patchi][facei] < 0.0) { nBf[patchi][facei] = 1.03; } else { nBf[patchi][facei] = 0.5*sqrt(3.0)*sin(phi_.value()); } mBf[patchi][facei] = nBf[patchi][facei]-1; if (!(pcBf[patchi][facei] > 0.0)) { pcBf[patchi][facei] = small; } if (mBf[patchi][facei] > 0) { nuBf[patchi][facei] = sqrt(2.0)*pf.boundaryField()[patchi][facei]*sin(phi_.value())* ( nBf[patchi][facei]-(nBf[patchi][facei]-1.0)*pow(pfBf[patchi][facei]/pcBf[patchi][facei], 1/mBf[patchi][facei]) ) /(sqrt(UsBf[patchi][facei]) + small); } else { nuBf[patchi][facei] = sqrt(2.0)*pf.boundaryField()[patchi][facei]*sin(phi_.value())* ( nBf[patchi][facei]-(nBf[patchi][facei]-1.0)*pow(pcBf[patchi][facei]/(pfBf[patchi][facei]+small), mag(1/mBf[patchi][facei])) ) /(sqrt(UsBf[patchi][facei]) + small); } } } } nu.correctBoundaryConditions(); Us.correctBoundaryConditions(); pc.correctBoundaryConditions(); Ud.correctBoundaryConditions();结果在相分数0.5左右(摩擦黏度产生处)报错:

相分数出现突变,而且无法增大(继续堆积),增大就会报错,不知道是哪个地方的处理有问题,还请东岳老师和其他前辈能解答一二!

-8

-8 -2006

-2006