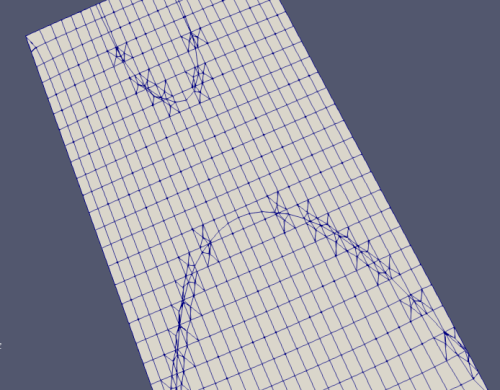

snappyHexMesh为何怎么划分 还是会出现不均匀的错误网格?。快疯了

-

snappyHexMesh为何怎么划分 还是会出现不均匀的错误网格?。快疯了 求解答下

!

!这个是snappyHexMeshDic

castellatedMesh true; // make basic mesh ? snap true; // decide to snap back to surface ? addLayers true; // decide to add viscous layers ? geometry // Load in STL files here { inlet.stl {type triSurfaceMesh; name inlet;} outlet.stl {type triSurfaceMesh; name outlet;} part1.stl {type triSurfaceMesh; name part1;} part2.stl {type triSurfaceMesh; name part2;} volume.stl {type triSurfaceMesh; name volume;} }; castellatedMeshControls { maxLocalCells 1000000; //max cells per CPU core maxGlobalCells 2000000; //max cells to use before mesh deletion step minRefinementCells 0; //was 0 - zero means no bad cells are allowed during refinement stages maxLoadUnbalance 0.1; nCellsBetweenLevels 1; // expansion factor between each high & low refinement zone // Explicit feature edge refinement // ~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~ features // taken from STL from each .eMesh file created by "SurfaceFeatureExtract" command ( {file "inlet.eMesh"; level 0;} {file "outlet.eMesh"; level 0;} {file "part1.eMesh"; level 0;} {file "part2.eMesh"; level 0;} ); // Surface based refinement // ~~~~~~~~~~~~~~~~~~~~~~~~ refinementSurfaces // Surface-wise min and max refinement level { inlet {level (0 0);} outlet {level (0 0);} part1 {level (0 0);} part2 {level (0 0);} } resolveFeatureAngle 80; // Resolve sharp angles // Default 30 refinementRegions // In descending levels of fine-ness {} // was ((0.001 4) (0.003 3) (0.01 2)) locationInMesh (0.01 0 0); //to decide which side of mesh to keep ** allowFreeStandingZoneFaces true; } // Settings for the snapping. snapControls { nSmoothPatch 3; tolerance 2.0; nSolveIter 30; nRelaxIter 5; nFeatureSnapIter 10; // default is 10 // New settings from openfoam 2.2 onwards for SHMesh implicitFeatureSnap false; // default is false - detects without doing surfaceFeatureExtract explicitFeatureSnap true; // default is true multiRegionFeatureSnap false; // deafault is false - detects features between multiple surfaces } addLayersControls //add the PATCH names from inside the STL file so STLpatchName_insideSTLName { relativeSizes false; // was true layers { } expansionRatio 1.3; finalLayerThickness 0.00016; //was 0.00016 minThickness 0.00008; //was 0.00008 nGrow 0; // was 1 // Advanced settings featureAngle 80; // was 70 //- When not to extrude surface. 0 is flat, 90 is right angle. nRelaxIter 3; //- Max# of snapping relaxation iter. Should stop before upon reaching a correct mesh. nSmoothSurfaceNormals 1; nSmoothNormals 3; nSmoothThickness 10; maxFaceThicknessRatio 0.5; maxThicknessToMedialRatio 0.3; thickness to medial distance is large minMedianAxisAngle 130; nBufferCellsNoExtrude 0; nLayerIter 50; } meshQualityControls { maxNonOrtho 65; maxBoundarySkewness 20; maxInternalSkewness 4; maxConcave 80; minFlatness 0.5; minVol 1e-13; minTetQuality 1e-9; minArea -1; minTwist 0.02; minDeterminant 0.001; minFaceWeight 0.02; minVolRatio 0.01; minTriangleTwist -1; // Advanced nSmoothScale 4; errorReduction 0.75; } // Advanced debug 0; mergeTolerance 1E-6;